The production line management system based on RFID radio frequency identification technology is to apply advanced RFID automatic identification technology in the production line, product transfer area and temporary storage warehouse, and use repeatable read and write RFID electronic tags, each RFID electronic tag has a unique ID number , as well as the readable and writable data area, write product information into RFID electronic tags, install readers at production line off-line stations and warehouse entrances and exits, automatically write and collect product information at each location through RFID reading and writing tag information, and communicate with Other MES systems share data information, and the information is displayed on the display screen at the same time, prompting to the production line operator, so as to track and manage the whole process of the products that need to be processed from offline to warehouse transfer, temporary storage, and then on-line production, so that To ensure the correspondence between the batch numbers of the goods between the production lines, each production line can complete the production tasks without error, and record important information in the production process, which can provide basic data services for future quality information traceability.

The main function:

1. Station management, generally used in piecework production occasions, employees use their ID Cards to start work, read the RFID electronic tags on the products to record the information of processed products, the main functions are to record employee attendance and work quantity information; record product information, Provide dynamic progress information, and find production line capacity bottlenecks through data analysis, providing a basis for flexible production.

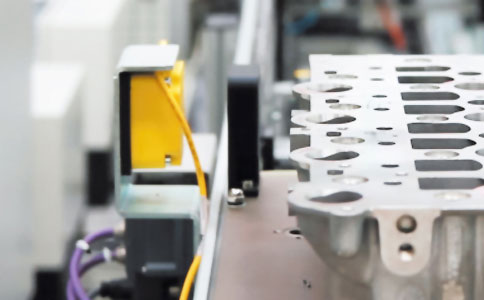

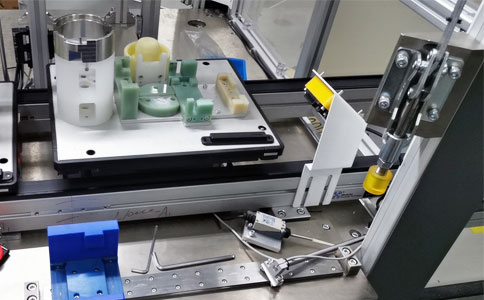

2. Automated production line management. In the application of automated production lines, RFID electronic tags are installed on products or carriers, and the RFID Readers of the production line are used to read product information, so as to provide processing attribute basis for automatic processing.

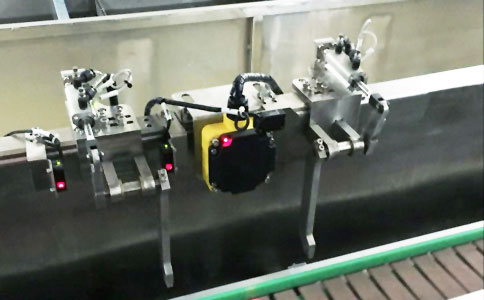

3. Supermarket management of the production line track, install RFID readers in the loading area of the production line, read the information of the material box or workpiece, provide a basis for rapid replenishment, and improve production efficiency.

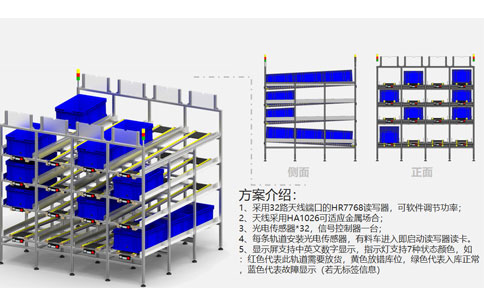

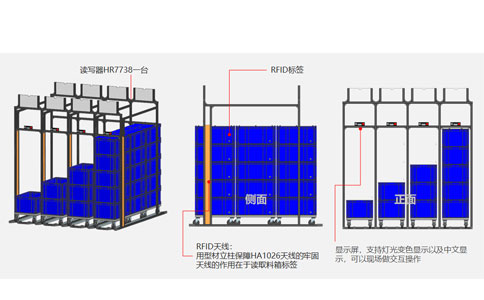

4. RFID management of fluent racks, install RFID electronic tag readers and small display screens on each fluent racks, automatically record the batches and quantities of feeding materials, and provide feeding forecast information in time, and light prompt the feeding port when feeding materials And display batch material name and other information.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China