The main function:

1. Effectively prevent tool loss and theft;

2. Simplify the registration process for tools entering and exiting the warehouse:

3. Avoid errors caused by manual management, and avoid inventory shortages or management negligence;

4. Locate tools in real time and accurately query and track tools:

5. Prevent safety accidents caused by lost tools

Parameters:

Protocol: ISO 18000-6C/EPC C1G2, ISO 18000-6B;

Optional support GB/T29768-2013 (national standard)

Working frequency: 840MHz~960MHz

RF output power: adjustable from 5 to 33dBm

Cabinet capacity: ≥150 pieces (with metal objects, they need to be placed in a standard manner)

Power supply voltage: AC220V±10%/50Hz±1Hz

Network interface: 10M/100M adaptive Ethernet interface (4G communication optional)

Temperature and humidity control: support adjustable, real-time meter display

Surface treatment: sheet metal powder spraying

Shielding performance: ≤5cm

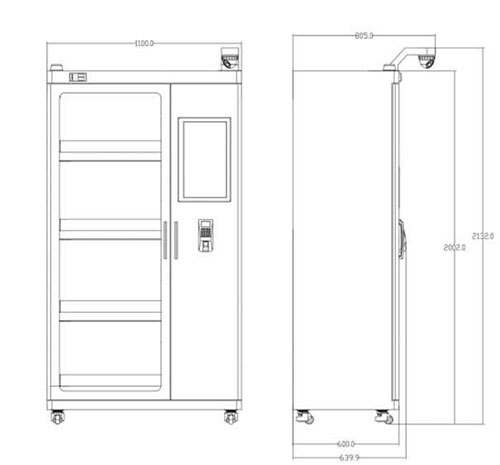

Dimensions: 1100 mm(W)×600mm(L)×2000mm(H) (including casters)

UHF RFID comprehensive management cabinet for Tools and tools, mainly used for management of tools, signs, etc. Passive RFID tags are used to uniquely identify tools. When tools are picked up or returned, permissions are managed through passwords, card swiping, fingerprints, etc. and the door is opened, and the person responsible for use is recorded. After closing the door, the cabinet automatically takes inventory and records the use. Number and type of tools.

UHF RFID comprehensive management cabinet for tools and equipment, compliant with IS018000-BC (EPC C162) protocol, with simple and beautiful appearance, stable quality and reliable performance. It integrates a 21.5-inch capacitive touch screen for convenient interactive operation, supports constant temperature dehumidification function, and the cabinet supports RFID It reads multiple tags and uses network ports for data transmission. It is a high-performance, easy-to-operate RFID intelligent management cabinet dedicated to tools, signage and other scenarios.

· Equipped with RFID automatic identification, which can record the receipt details of items in the cabinet in real time;

·Built-in dehumidifier, which can maintain constant temperature and humidity to maintain a good storage environment in the cabinet;

· Equipped with alarm lights to remind you of illegal use;

·Equipped with an emergency unlocking device, the emergency key can be used to unlock the door during a power outage or malfunction.

·High-definition surveillance camera can record the status of the cabinet in real time, making it easy to trace and record;

·A variety of cabinet layout configurations, 4-8 layers of shelves can be configured according to the items (default 4 layers); signage management is optional

· Equipped with partitions, 25 cells per floor;

·21.5-inch high-definition touch screen, sensitive touch, easy to operate, and elegant in appearance;

·Equipped with central password fingerprint all-in-one machine, supporting card swiping function.

Application scenarios of RFID smart tool management in different industries

1. Management of railway line maintenance tools. There are many types of railway line maintenance tools and their use cases are scattered, which has always been a difficulty in management. After each tool is equipped with an RFID electronic tag, an RFID ultra-high frequency reader can be installed at the door of the warehouse for identification. For incoming and outgoing tools and authorization management, UHF readers can also be installed on construction vehicles to monitor the tools on the vehicles in real time, bring back as many as you take out, and provide real-time reminders when tools are left behind.

2. Aircraft repair tool management. There are many types of aircraft repair tools and parts and their prices are high. Airlines have always expected to achieve more intelligent management. RFID electronic tags are installed on the parts and tools and placed on the RFID Reader. In the box of the writer, the reader/writer in the box is powered by a battery, and the data is connected to the cloud in real time through wireless means. The operator can request the tool box through the APP. After the repair work is completed, the tools that should be returned can be checked on the APP. Whether to put it back or not, the actual location of all tools and tool boxes can be checked in the background management software, as well as the status of the person who took them out and the status of the tools inside.

3. Management of production tools for large-scale equipment such as high-speed rail and shipbuilding. When large-scale equipment is produced, the production site area is large and there are many types of tools involved in the construction of various sections, which brings great difficulties to the management of tools. The use of RFID smart tools Behind the cabinet, tool management becomes simple. UHF reading and writing equipment is installed in the tool cabinet to monitor the tools in the cabinet in real time. The display screen on the cabinet can display the type and quantity of tools in real time. The operator only needs to swipe a card or press a fingerprint to open the tool cabinet. When tools are taken out from the tool cabinet door and returned, the equipment automatically records and records the return of tools in the tool cabinet, preventing tools from falling and saving workers time in tool management.

4. Tool management in prison workplaces. Prison workplaces are special occasions. Risky materials such as tools must be strictly managed. Losing one piece will bring great safety risks. This is why RFID smart tool cabinets are needed. , realize collection by person and item, and real-time monitoring of the location and usage of tools. The system automatically warns when encountering risky situations, which plays a role in risk prevention.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China