◆ Power supply mode: DC 24V

◆ Power consumption: 1W;

◆Circuit protection: with reverse polarity protection;

◆ Working frequency: 134KHZ;

◆Protocol standards: FDX-B (recommended), EMID;

◆ Card reading distance: 0-70mm;

◆ Communication interface: RS485;

◆ Communication protocol: ModBus RTU;

◆ Working humidity: 10-90% RH;

◆ Working temperature: -25℃-+85℃;

◆ Protection level: IP-67;

◆ Shell material: ABS+aluminum alloy.

Physical and environmental properties:

Technical Parameters

Operating temperature: -25℃~85℃

Storage temperature: -40℃~90℃

Humidity: 10%~90% non-condensing state

Weight:150g

Drop test: 1.2 meters free fall

ESD performance: air discharge ±15KV, contact discharge ±8KV

Sealing standard: IP67

Electrical parameters:

Technical Parameters

Power supply mode: DC 24V

Power consumption: 1W

Circuit protection: with reverse polarity protection

Working frequency: 134KHZ

Protocol standards: FDX-B (recommended), EMID

Card reading distance: 0-70mm

Communication interface: RS485

Communication protocol: modbus RTU

Description:

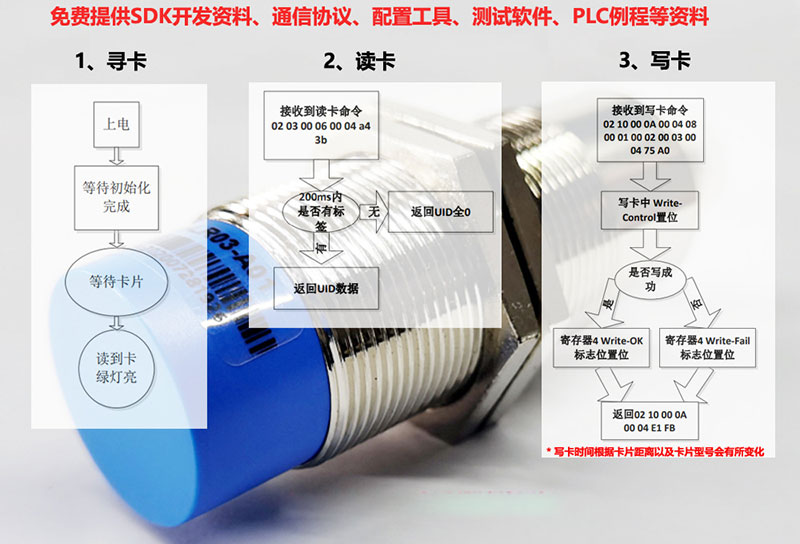

The low-frequency industrial RFID Reader RS485 cylindrical automated production line code carrier read-write head reader operates at 125KHZ & 134KHZ and supports reading of FDX-B and EMID standard protocol format tags, as well as FDX-B standard protocol format For tag writing, a 3-in-1 low-frequency reader/writer that integrates antenna, amplifier, and controller has the characteristics of small size and high integration. The reader/writer integrates the radio frequency wireless communication protocol. Users do not need to understand complex radio frequency communication protocols. They only need to perform simple access operations on the corresponding registers to complete changes to the tag data.

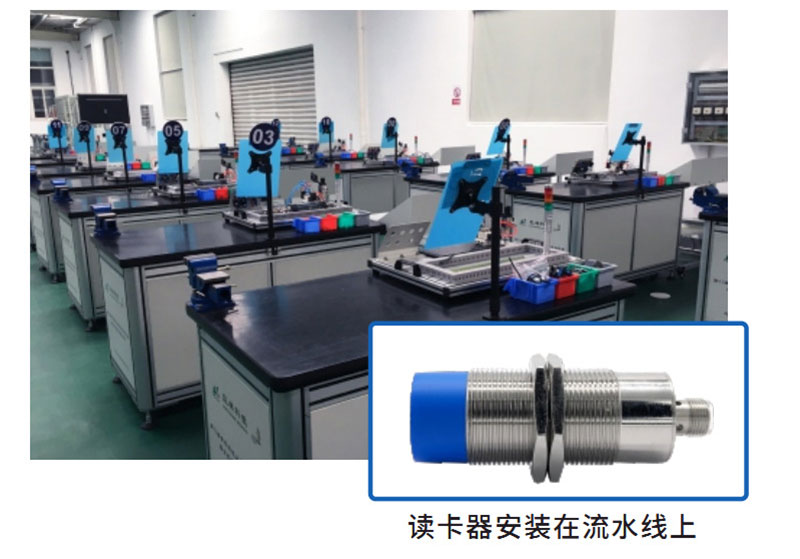

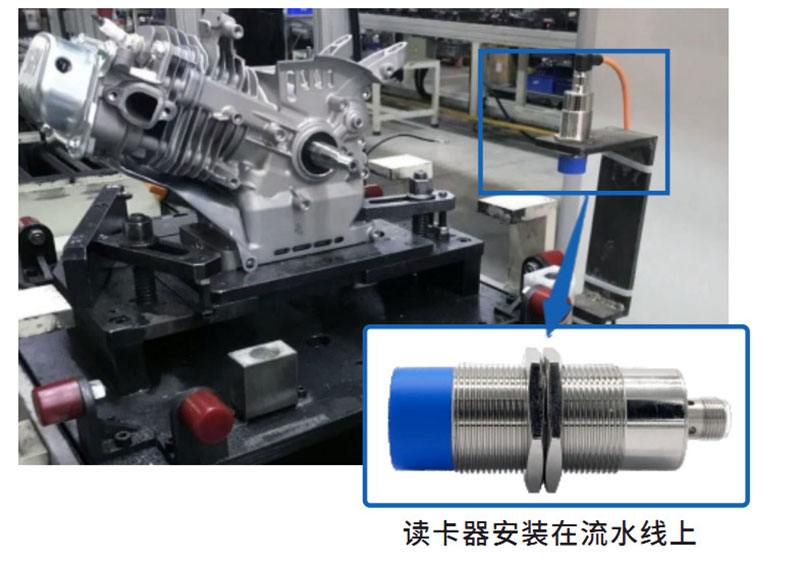

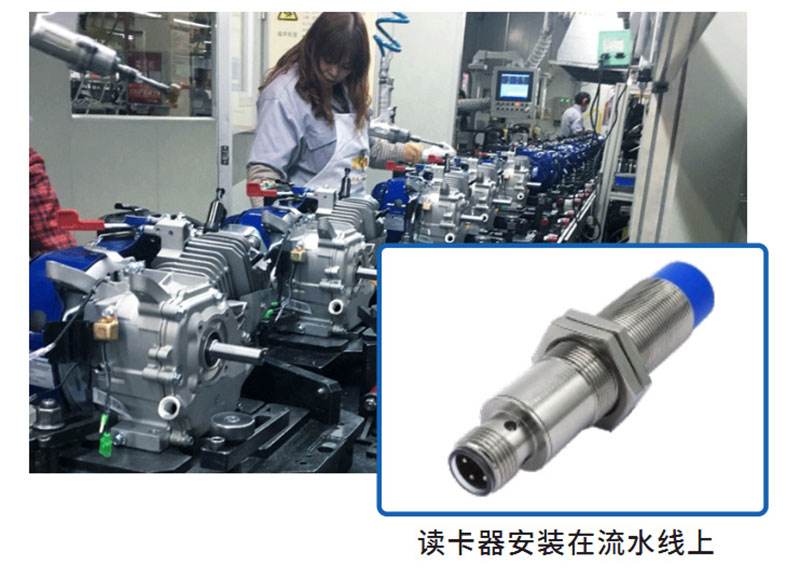

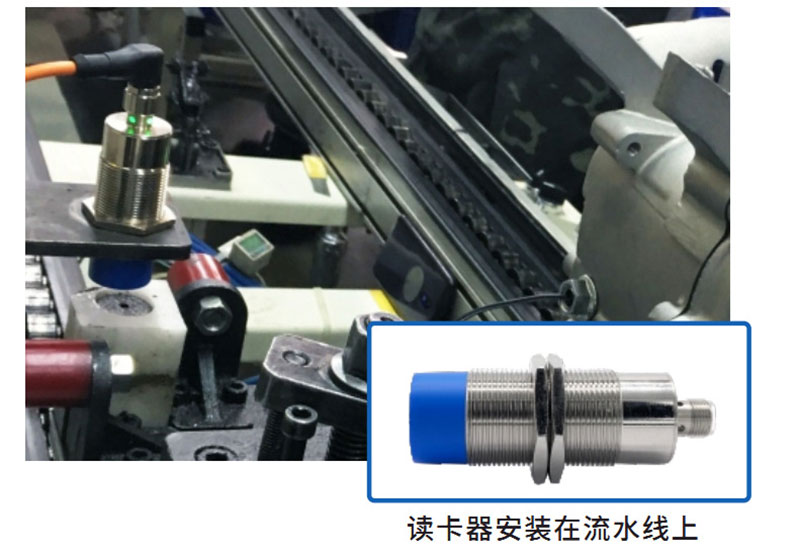

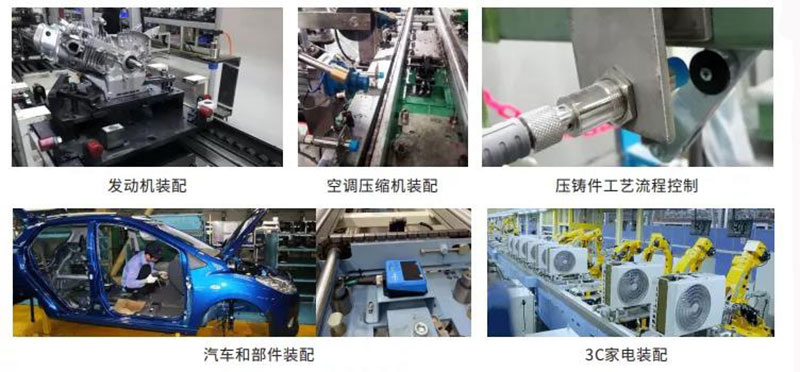

The communication interface of the low-frequency industrial RFID reader RS485 cylindrical automated production line code-carrying read-write head reader is an RS485 (Modbus RTU) industrial bus interface, which is convenient for users to access different control systems and is widely used in semiconductor automated production lines. , power lithium battery production line, automobile production line, etc. Automobile strut assembly line, automobile brake pad processing production line, air conditioning assembly line, radiator fan automatic test line, precision Tool management, engine assembly line, component assembly line, compressor production line, smart light assembly line, injection molding workshop intelligent distribution, turnover box automatic identification And fields such as distribution and AGV trolleys.

Features:

Supports command control and operation of PLC controllers and visual machine equipment of RS485 (Modbus RTU) communication protocol from Siemens, Omron, Schneider and other brands

Low frequency, small size, supports FDX-B format glass tube electronic tag reading and writing, 1.2 meters free fall, unscathed!

Easy to install, easy to fix, accurate and concentrated, these are the essence of industrial automation RFID identification and sensing equipment.

Industrial automation RFID identification and sensors are widely integrated and applied to high-end and sophisticated equipment such as various automated workshops, assembly lines, assembly lines, and robot arm automatic controls to reduce manual judgment, intervention, error rates, and ensure product quality. Select a device.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China