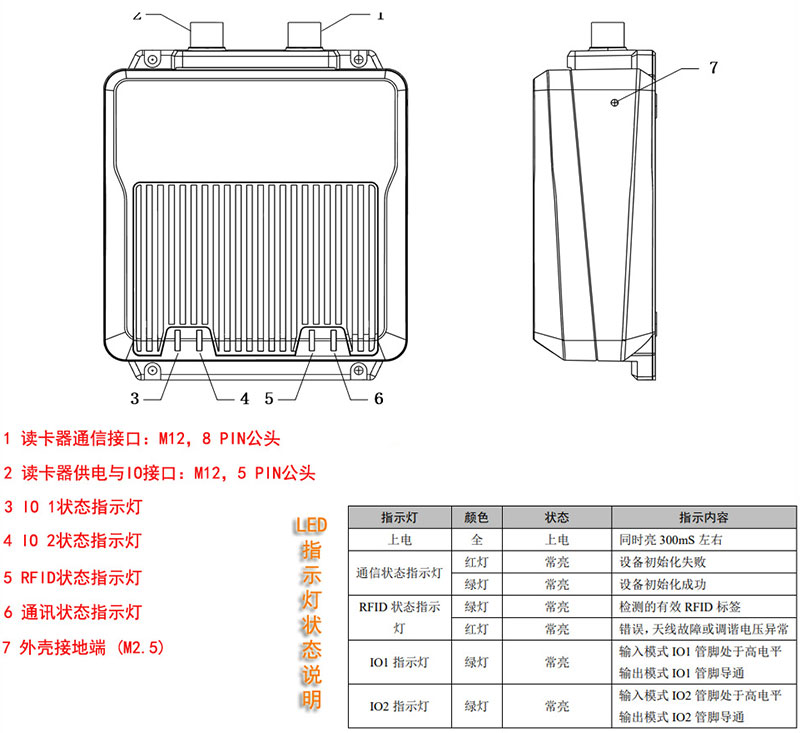

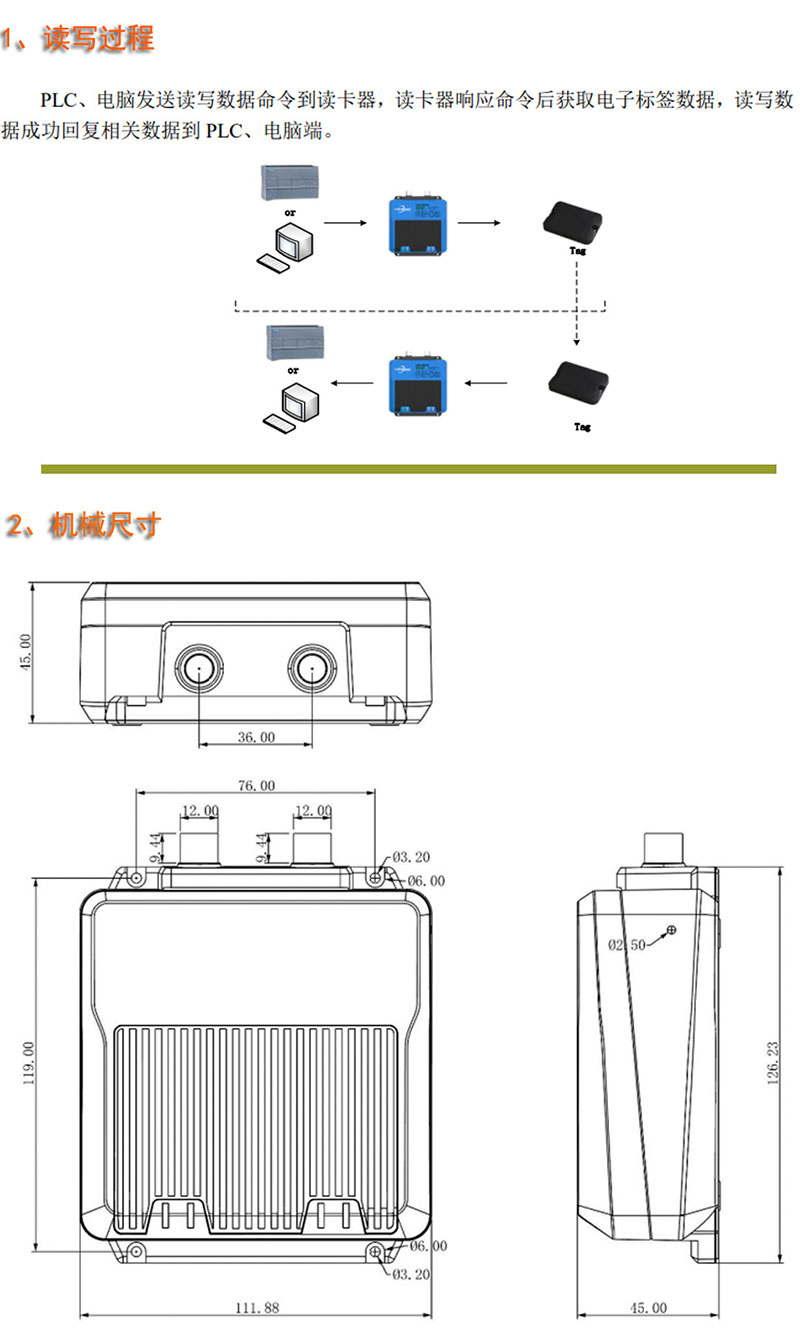

RS232|485 MODBUS RTU low-frequency industrial RFID reader/writer encoder reader with IO signal,it is a low-frequency RFID tag reader based on radio frequency identification technology. The RFID operating frequency is 134K and supports reading of FDX-B and EMID standard protocol format tags, as well as writing of FDX-B standard protocol format tags.

RS232|485 modbus RTU low-frequency industrial RFID Reader/writer encoder reader with IO signal, and supports the standard industrial communication protocol MODBUS RTU, which is convenient for users to integrate into control systems such as PLC. The card reader integrates the radio frequency communication protocol. Users only need to receive data through the communication interface to complete the tag reading operation without having to understand complex radio frequency communication protocols.

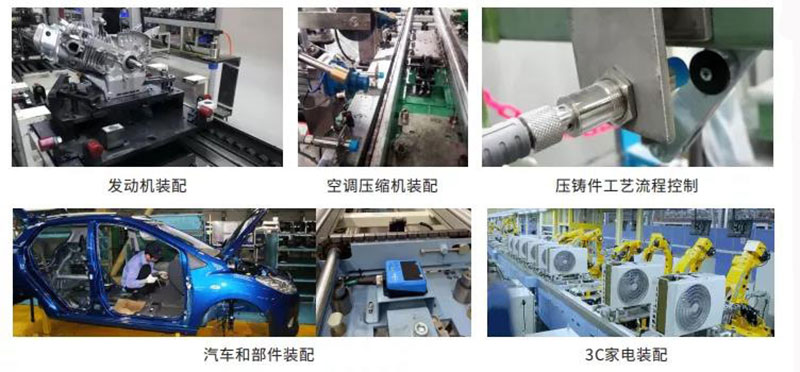

Application areas:

Engine process management

Compressor automated production line

Toilet automated production line

3C home appliance automation assembly line

Battery automation production line

Automatic production line for electroplating industry

Parameter:

◆ Power supply mode: DC 24V

◆ Power consumption: 1W;

◆Circuit protection: with reverse polarity protection;

◆ Working frequency: 134KHZ;

◆Protocol standards: FDX-B (recommended), EMID;

◆ Card reading distance: 0-140mm (different according to the tag model);

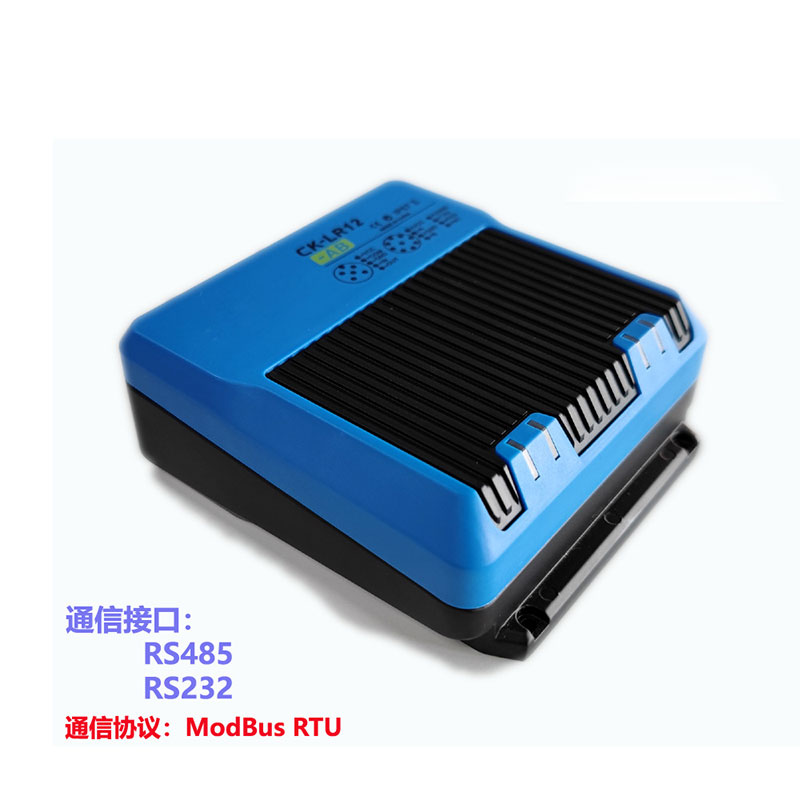

◆ Communication interface: RS485, RS232;

◆ Communication protocol: ModBus RTU;

◆ Working humidity: 10-90% RH;

◆ Working temperature: -25℃-+85℃;

◆ Protection level: IP-67;

◆ Shell material: ABS+aluminum alloy.

1. Physical and environmental characteristics:

Technical Parameters

Operating temperature: -25℃~85℃

Storage temperature: -40℃~90℃

Humidity: 10%~90% non-condensing state

Weight: 210g

Drop test: 1.2 meters free fall

ESD performance: air discharge ±15KV, contact discharge ±8KV

Sealing standard: IP67

2. Electrical parameter indicators:

Technical Parameters

Power supply mode: DC 24V

Power consumption: 1W

Circuit protection: with reverse polarity protection

Working frequency: 134KHZ

Protocol standards: FDX-B (recommended), EMID

Card reading distance: 0-140mm (different according to tag model)

Communication interface: RS485, RS232

Communication protocol: ModBus RTU

Industrial RFID reader application fields

1. Production line management:

Power battery production line, photovoltaic cell production line, home appliance mixed flow production line, automobile production line management, AGV automatic feeding vehicle positioning, hanging sorting system management and control

2. Automobile industry:

RFID tags are widely used in various process sections of automobile parts production and automobile manufacturing. They quickly improve operational efficiency from the source for the production management of a large number of parts and the control of complex manufacturing processes and procedures. RFID sensing equipment has formed mature application solutions in automobile factory welding workshops, electroplating, spraying, painting workshops, final assembly workshops, powertrain workshops, etc., and plays an irreplaceable role.

3. New energy power battery:

RFID sensing equipment can provide unmanned, automatic and real-time identification of battery cell bins on the power battery production line. It uses real-time collected bin information and binning information to complete hybrid automatic testing equipment control, cell parameter transmission, and cell voltage. There are needs such as binning, real-time push of process guidance, verification of encapsulation process, and docking of various automation equipment.

4. Home appliance 3C manufacturing industry:

Through the RFID system, real-time collection of production process data, automatic identification of material data, free scheduling of process parameters and test procedures for each station are achieved, achieving the goals of production line rhythm control and line balance rate priority. RFID sensing equipment interacts with RFID code carriers in real-time data, collects and connects with MES system in real time through PLC or industrial computer, completing functions such as product information tracking and management, automatic docking of testing equipment, quality traceability, and free marking.

5. Warehousing and logistics:

RFID sensing equipment automatically collects data from various operational links such as warehouse distribution, warehousing, outbound, warehouse transfer, and inventory counting, ensuring the speed and accuracy of data input in all aspects of logistics and supply chain management, and ensuring timely Accurately grasp inventory status and in-transit data, and maintain and control inventory reasonably.

6. Other industries:

Mechanical equipment operation authority management and control, production site log management, semiconductor industry, mold Tool identification, etc.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China