The radio frequency communication protocol is integrated inside the sensor. Users only need to receive data through the RS232|RS485 communication interface to complete the tag reading operation without having to understand complex radio frequency communication protocols.

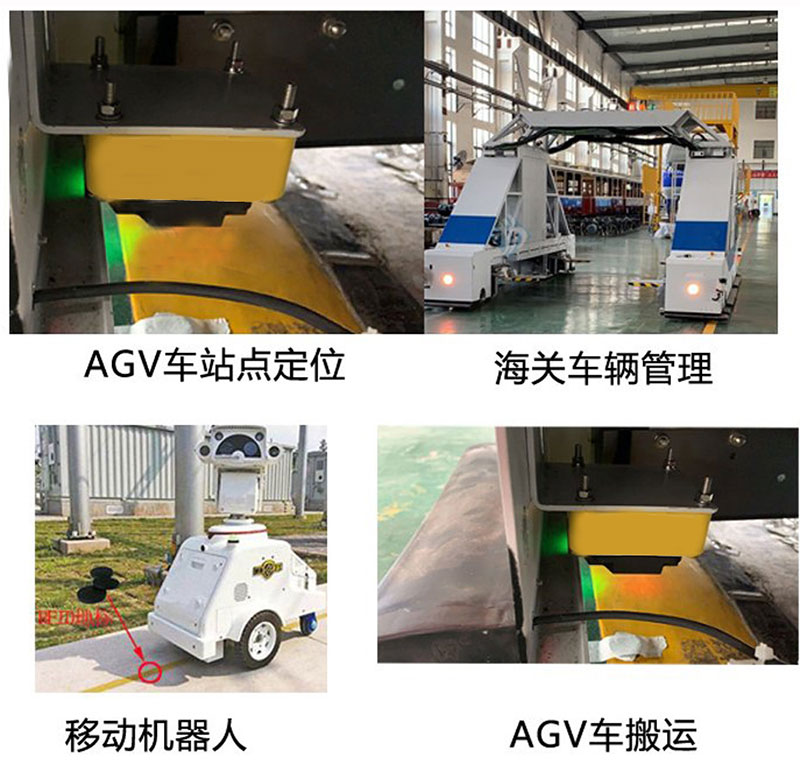

It is widely used in AGV trolleys, aerial suspended trolleys EMS, RGV trolleys, three-dimensional warehouses, warehouse management, supermarket suspended conveyor lines, AGV inspection robots, AGV handling robots, fruit and vegetable shed picking robots, car wash stations, etc.

Description:

It comes with an Auto-turning automatic tuning circuit, which can automatically adjust circuit parameters when working in different environments. It has strong anti-interference ability, high receiving sensitivity, stable performance, and strong reliability.

RS232 serial communication AGV car landmark sensor positioning tag RF collector navigation card reader CK-G06 is an AGV landmark card reader specially designed for AGV unguided cars based on radio frequency identification technology. It integrates antenna, amplifier and controller into one, classic durable.

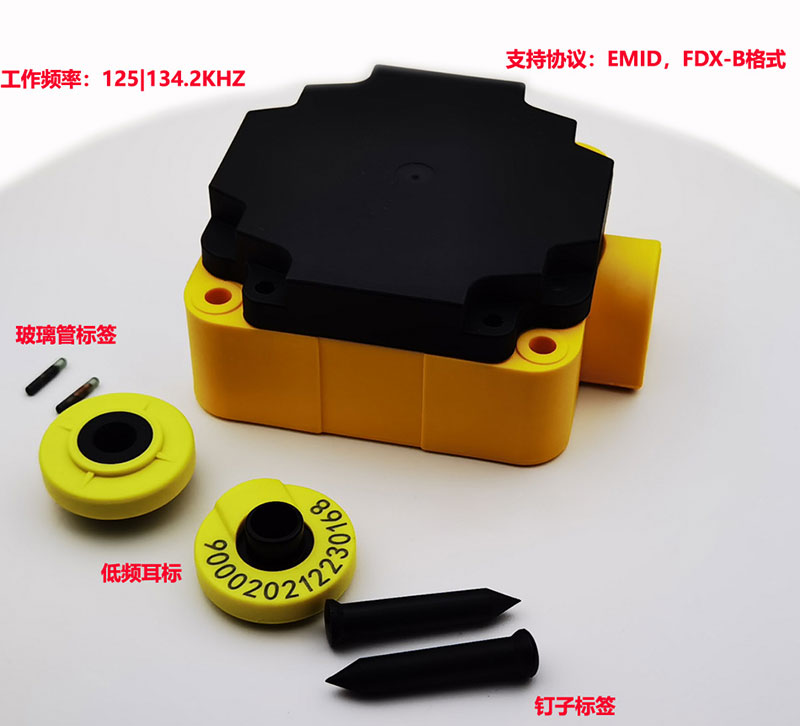

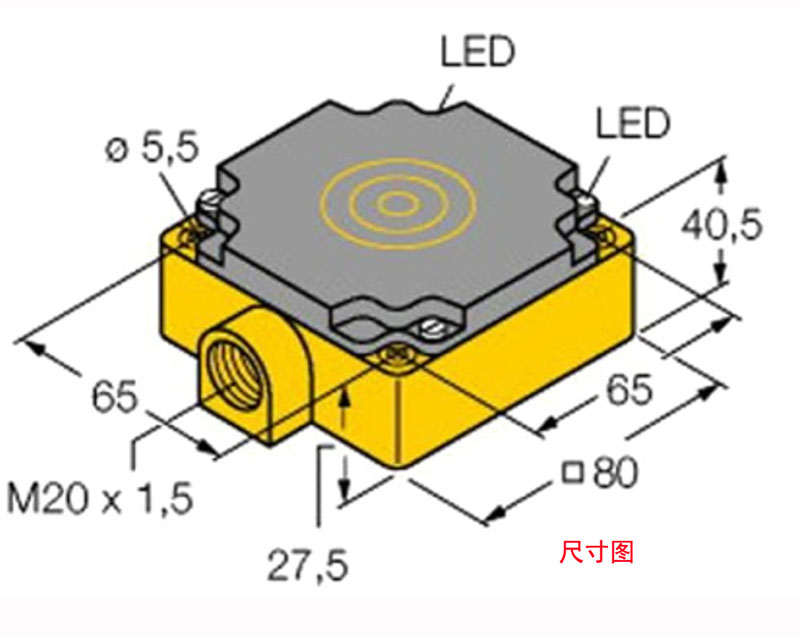

The card reader adopts a square appearance design and supports operating frequencies of 134.2KHZ and 125KHZ. It supports reading tags in two protocol formats: FDX-B and EMID. It supports the standard industrial MODBUS RTU fieldbus protocol to facilitate network communication. The rate can be configured up to 115200. The card reader integrates the radio frequency communication protocol and can be connected to PC/PLC/SCM. Users only need to receive data through the RS232/RS485 communication interface to complete the tag reading operation without having to understand complex radio frequency communication protocols.

RS232 serial communication AGV car landmark sensor positioning tag RF collector navigation card reader CK-G06 power supply with 26V, 5000W TVS tube, anti-surge protection and polarity reverse protection; the card reader comes with Auto-turning 16-level automatic tuning The circuit can automatically adjust circuit parameters when working in different environments, minimizing the impact of the external environment on the card reading distance, further enhancing its own anti-interference ability, and having the characteristics of high receiving sensitivity, stable performance, and strong reliability.

Parameters:

◆ Working voltage: 10-26 V

◆ Power: 1.2 W

◆ Current consumption: <0.2A

◆Circuit protection: with reverse polarity protection

◆ Working frequency: 134.2KHZ, 125KHZ

◆ Recognition speed: 2m/s

◆ Card reading distance: 0-180mm

◆Supported tag types: FDX-B, EMID

◆ Communication interface: RS232 / RS485

◆ Working humidity: 10-90% RH (no condensation)

◆ Working temperature: -25℃-+70℃

◆ Protection level: IP54

◆ Shell material: ABS Engineering plastic

◆ Wiring method: terminal block

◆ Installation method: M4 screws, 4 mounting holes

Installation instructions and precautions

1) It is not recommended to install the card reader directly on a metal surface. The distance between the card reader and the metal surface can be adjusted through plastic spacers, long screws or customized brackets.

2) The card reading surface of the card reader cannot be blocked or surrounded by metal materials. The distance between the side of the card reader and the metal structure should be greater than 20mm.

3) The card reader should be kept as far away from motors, power modules and other devices that are prone to electromagnetic interference.

4) Electromagnetic radiation from other devices around the card reader may reduce the sensitivity of the card reader or cause card reading failure. Appropriate radiation shielding measures should be taken for devices that are prone to electromagnetic radiation.

5) Install the card reading surface toward the label card. The label card can be in the center of the card reading surface. The card reading surface and the label card should be kept as horizontal as possible to avoid tilting.

6) The distance between the card reader and the tag card is 10% to 70% of the maximum sensing distance. If high-speed card reading is required, it is recommended that the distance be controlled at 10-20mm.

7) The card reader can only read one tag card at a time, so do not place two tag cards within the card reading range. The distance between the two tag cards should be greater than twice the length of the card reader.

8) It is best to install the tag card on a straight line, not at a turn or branch road bifurcation to avoid missing readings.

9) Normal label cards cannot be directly attached to metal plates. If this cannot be avoided, please use the T354AE special anti-metal label. Metal structures, wires and cables near the card will affect the sensitivity of card reading or cause card reading failure. You should try to avoid installing the card in these places.

10) The label card contains a precision induction coil. To maintain a long service life, please try to avoid stepping on or crushing it.

signal indication

Red LED: Power indicator light

Green LED: Tag detection indicator light

Sensor working process

After the sensor is connected to the power supply, the red LED lights up and the sensor enters automatic adjustment.

state and tune its own parameters according to the working environment.

When the sensor detects the presence of an RFID tag, the green LED

Lights up while transmitting data to the receiver through the RS232 interface.

Communication Interface

Communication interface: RS232

Data format: 1 start bit, 8 data bits, no parity bit, 1 stop bit

Baud rate: 9600

Output encoding format: ASCII code

communication process

The sensor supports two communication modes: AutoSend mode and ReSend mode.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China