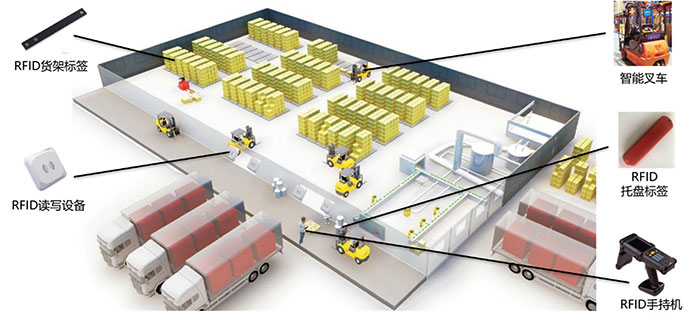

The RFID warehousing and logistics management system adopts RFID automatic identification technology to install electronic tags on the goods and storage locations in the warehouse, to give each product and storage location an identification, or to identify the pallet, so that the goods are associated with the storage location; realize warehouse management Rapid identification, automatic, efficient, and batch collection of information in key operations such as warehousing, warehousing, moving, inventory, and transportation.

Install a UHF antenna and RFID Reader at the gate of the warehouse. When the goods pass through the gate, the cutting infrared activates the RFID reader to work, and the RFID tag will be read by the reader, so that the entry and exit can be known by counting the number of tags. The quantity of goods, and then use the warehousing software to automatically process the in and out of the warehouse, and complete the automatic in and out of the warehouse.

The process of counting is completed by using the RFID handheld device. The staff will hold the RFID handheld device to read the data on the goods to be counted. You can enter the name of the goods to find the location of the goods in the warehouse.

Install RFID electronic tags on the shelves to identify the shelves. At the same time, install RFID readers and on-board computers on the forklifts to realize the association between goods and shelves; read the labels of shelves and goods through forklift readers. It can accurately record the storage location of the goods, and at the same time provide the location information of the forklift in the warehouse, so as to deploy the forklift (see related solutions for forklift modification).

Features of RFID radio frequency technology:

1. Automatic in and out of the warehouse: the stable reading and writing distance of the handheld reader can reach 2-5 meters, and the reading and writing distance of the fixed reader can reach more than 12 meters. It effectively solves the problem of manually scanning barcodes in barcode storage in the past, realizes automatic warehouse entry and exit, and greatly improves storage labor costs and forklift use efficiency.

2. Dozens of hundreds of tags can be read instantly: as soon as the tag enters the magnetic field, the RFID reader can read the tag information immediately; using RFID anti-collision technology and UHF fixed reader, it can be read instantly Dozens of labels, greatly improving scanning efficiency and reducing labor costs.

3. Unobstructed reading: When scanning traditional barcodes, the labels cannot be blocked. RFID can penetrate non-metallic and non-liquid materials such as paper, wood and plastic for penetrating communication without a light source. Provide a better scanning experience, which can quickly tally, find goods, and take inventory. is a warehouse management accelerator.

4. Large data capacity: the capacity of a one-dimensional barcode is 50 Bytes, the maximum capacity of a two-dimensional barcode can Store 2 to 3000 characters, and the maximum capacity of an RFID electronic tag is several MegaBytes. With the development of memory carriers, the data capacity also has a tendency to expand continuously. In the future, the amount of data required to be carried by items will increase, and the demand for expanded capacity of tags will also increase accordingly.

5. Long service life, adapt to harsh environment: RFID radio communication method, so that it can be used in high pollution environment and radioactive environment such as dust and oil pollution, with a life span of more than 10 years (100,000 reads and writes); traditional barcode carrier label Paper is susceptible to contamination. In addition, because the barcode is attached to the plastic bag or the outer carton, it is particularly vulnerable to damage; the RFID tag stores the data in the chip, so it can be free from contamination, and the RFID has strong anti-pollution ability and durability.

6. Reuse: The content of the RFID tag can be changed. The direct benefit is that the RFID electronic tag can be reused, getting rid of the situation that the traditional barcode label can only be used once, which can effectively reduce the cost of enterprise consumables (enterprises using the barcode storage system have to purchase a large number every year. labels and ribbons)

7. Security: RFID electronic tags can not only be embedded or attached to products of different shapes and types, but also can set password protection for the reading and writing of tag data, which has higher security;: because RFID carries electronic information , its data content can be protected by a password, so that its content is not easy to be forged and fabricated, and the security is higher.

8. Miniaturized size and diverse shapes: RFID does not need to match the fixed size and printing quality of paper for reading accuracy, and is more suitable for the development of miniaturization and various forms, so as to facilitate embedding or attaching to products of different shapes and types superior.

Program Features

Automatic identification of goods in batches

Use the RFID handheld terminal to bind the RFID and the goods on site, saving the time of printing the RFID label and manually matching the label to the goods, and greatly improving the efficiency of goods identification.

1. After the arrival of the goods, paste the pre-prepared RFID labels on the goods (no need to check whether the RFID labels correspond to the goods);

2. After all the goods are labeled, select the product number, specification and other information of the goods on the handheld RFID reader;

3. Use a handheld RFID reader to scan the tagged goods, the system automatically associates the RFID tags with the goods in batches, and the goods identification is completed

RFID location

Use the RFID electronic tag to identify the storage location, and the RFID storage location tag number read by the wireless PC and RFID reader on the forklift can ensure that the goods are placed in the correct position. The location label generally uses an anti-metal RFID label.

Ultra-high scanning speed

Barrier-free reading, dozens of labels can be scanned at the same time, a new scanning method, which greatly improves storage efficiency and reduces storage costs.

storage advantage

The tag storage capacity is large, and some tags can store several M data, even ordinary RFID tags can store hundreds of K data, and the size of the tag is not affected by the amount of stored data, and enough cargo information can be stored in the tag.

reuse

The service life of RFID tags is generally greater than 10 years (100,000 reads and writes), and the content can be changed, so RFID tags can be reused, and RFID tags can be recycled to reduce enterprise storage costs.

Improve forklift utilization

Install RFID readers and on-board computers on forklifts to realize the association between goods and shelves; read the labels of shelves and goods through forklift readers, which can not only accurately record the storage location of goods, but also provide forklifts in the warehouse. The location information in the system can be used to deploy forklifts. The location and status of each forklift can be grasped in real time, the scheduling of forklifts can be more flexible, and the utilization rate of forklifts can be maximized.

Automated storage

When there is a new incoming order:

1. The system selects idle forklifts according to the forklift scheduling plan, and sends the storage order to the tablet computer of the forklift.

2. The forklift driver removes the pallet according to the warehousing instruction received by the tablet computer, and the reader on the forklift reads the pallet label information and compares it with the information on the warehousing instruction to ensure that the operated goods are consistent with the received warehousing instruction.

3. When the forklift passes through the RFID warehouse door, the reader on the warehouse door reads the electronic tag on the forklift, opens the card door after confirming the identity, and sends the read forklift information and pallet label information to the background.

4. After the forklift arrives at the target location, the reader reads the label of the location, confirms that it is consistent with the target location of the instruction, puts the goods on the shelf, and sends an instruction back to the host system.

5. The host system confirms the warehousing and generates a document to update the database, and records the operation log.

Automated delivery

When there is a new outbound order:

1. The host system selects an idle forklift that is closer to the warehouse to be delivered, and sends the delivery command to the tablet computer of the forklift.

2. After the forklift driver arrives at the target location according to the detailed information on the pallet on the tablet computer, the reader reads the location and the label of the pallet, compares it with the delivery instruction, and removes the pallet after confirmation. If only part of the pallet is taken , needs to be manually picked to the target pallet.

3. After the picking is completed, send instructions to the host system to complete the delivery.

4. After all the picking is completed, use the RFID handheld to scan all the pallet labels, check with the shipping order information, and recover the pallet labels and send instructions to the host system after they are correct.

5. The host system confirms the delivery and generates a document to update the database, and records the operation log.

6. After all the details of the list are stored in the warehouse, the collected data and list data are checked, and the check results are sent to the customs supervision platform system.

Super Efficient Inventory

Using the RFID multi-label inventory function, you can quickly inventory the warehouse inventory, which greatly improves the problem of taking a lot of time for inventory scanning in the barcode method.

safety inspection

When the goods leave the warehouse, the system automatically judges that if they do not belong to the outbound goods (the goods specified in the outbound order), the system will automatically alarm to prevent the goods from being stolen.

Implementation benefits

5% to 10% increase in inventory availability

10% faster delivery

20% reduction in labor costs:

30% reduction in venue management fees

Increase throughput of warehouse products by up to 20%

Reduce damage rates and write-offs of expired merchandise by up to 20%

The application of RIFD intelligent warehouse management system ensures the speed and accuracy of data input in each link of cargo warehouse management, ensures that enterprises can grasp the real data of inventory in a timely and accurate manner, and maintain and control enterprise inventory reasonably. Through scientific coding, it is also convenient to manage the batches and shelf life of inventory goods. Using the warehouse location management function of the system, you can grasp the current location of all inventory goods in a timely manner, which is conducive to improving the efficiency of warehouse management.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China