RFID Jewelry management applied to new Retail Industry solutions

Throughout the management of the entire jewelry industry, most of the problems exist in the counter inventory of the monopoly point, but the current jewelry inventory work is basically done by manual operation, and the jewelry products are small in size and large in quantity. According to data, it takes an average of about five hours for an ordinary jewelry to perform an inventory of the products in the Store. The problem of inventory efficiency has led to the inability of each jewelry store to inventory products on a daily or weekly basis. At the same time, because jewelry is mostly high-value products, its indicators and parameters are cumbersome and professional, and it is easy to be lost when the personnel are crowded, and the shopping guide cannot respond quickly. At the counter with a large number of jewelry, the work of the shopping guide will be affected. It will cause a lot of pressure and easily lead to the theft of valuables. This kind of management and sales method, which relies entirely on human experience and ability, greatly restricts the business expansion and customer experience of the company.

RFID UHF system

a. Introduction to RFID UHF system

The system adopts Radio Frequency Identification (RFID) technology, which is a non-contact automatic identification technology. It automatically identifies target objects and obtains relevant data through radio frequency signals, and the identification work does not require manual intervention. RFID technology can identify high-speed moving objects and identify multiple tags at the same time, which is fast and convenient to operate.

Jewelry management based on RFID technology is to affix RFID tags to valuable jewelry products, combined with jewelry inventory equipment installed on the counter to monitor, control and track labeled jewelry, to achieve rapid inventory and real-time management functions. In this way, the in-out and sales process of jewelry products can be tracked and recorded in an all-round way, and the cumbersome and inefficient manual management and barcode scanning mode are replaced with new automated, accurate and efficient methods. Jewelry tags are RFID tags. Each tag has a unique ID number. The tag records the weight, purity, grade and other jewelry information on the national inspection certificate. RFID technology is introduced into jewelry management, and RFID tags are attached to valuable jewelry products. Combined with jewelry inventory equipment installed on the counter, it is used to monitor, control and track labeled jewelry to achieve rapid inventory, real-time tracking and intelligent sales management.

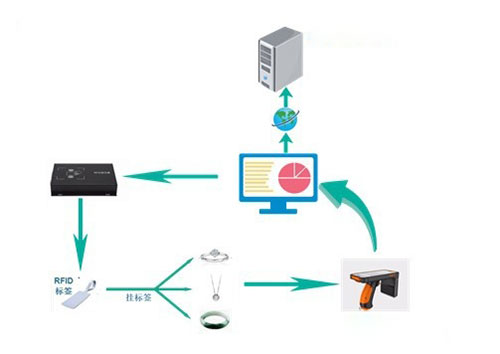

b. System composition

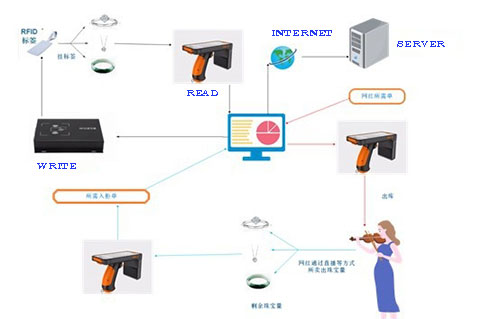

3. System workflow

3.1 Check inventory and write value

(1) Equip each piece of jewelry with an RFID tag, and write jewelry information through a reading and writing device.

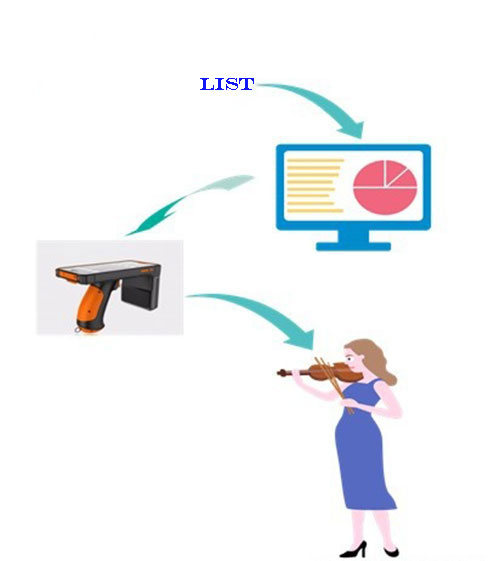

(2) The RFID handheld computer needs to check the jewelry. The handheld computer communicates with the system through the wifi module, and the system checks the jewelry information in real time.

3.2 Out of cabinet

Before checking out of the cabinet, put the displayed items in the radio frequency field composed of RFID Reader and RFID Antenna, and the RFID handset will collect all the jewelry label information in the display tray to complete the entry of the out-of-the-cabinet information.

3.3 Return to the locker

Before entering the cabinet, put the displayed items in the radio frequency field composed of RFID reader and RFID antenna, and the RFID handheld will collect all the jewelry label information in the display tray to complete the entry of the cabinet information.

System advantages

●Security: By embedding RFID chips into jewelry labels, anti-smuggling and anti-counterfeiting effects are realized;

●Economy: The software system and reader can be used for life after one investment, and only need to purchase labels in the follow-up;

Accurate: The data is accurate, and RFID tags can be accurately collected and identified in all aspects of the supply chain to ensure the accuracy of goods and prevent counterfeiting;

●RFID tag combined with one-dimensional bar code to ensure complete identification of physical evidence information.

●Each electronic label has a unique code, which can quickly identify physical evidence and will not cause confusion due to repeated codes.

●Prevent "entrainment" The physical evidence that is not registered in the system will not be mixed with the physical evidence that is normally out of the warehouse and taken away.

●Handheld computer and fixed reader-writer cooperate to improve the accuracy of the system.

●Automatic collection of access data to reduce human error.

●Reduce labor management costs.

●The label can be selected according to the actual situation.

●Automatic upload of data to improve work efficiency

●Easy to install and easy to expand.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China