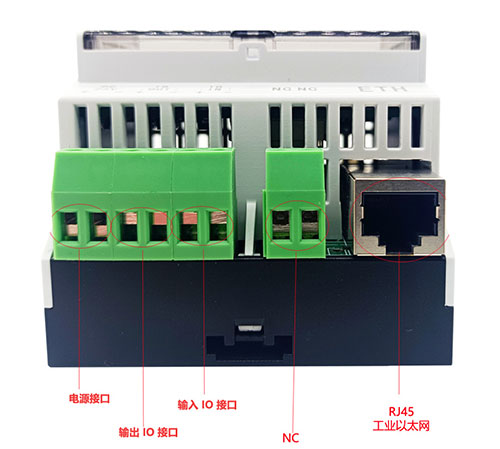

Power supply mode: DC 24V|POE power supply;

Power consumption: 1W;

Circuit protection: with reverse polarity protection;

Working frequency: 13.56MHZ;

Protocol standard: ISO15693;

Support maximum tag capacity: 8K Bytes;

Support label types: I-CODE2, I-CODE SLI;

Card reading distance: related to the read-write head and tag parameters;

Communication interface: RJ45;

Communication protocol: ModBus TCP (Industrial Ethernet);

Working humidity: 10-90% RH;

Working temperature: -25℃~+85℃;

Shell Material: Polycarbonate.

Installation method: DIN rail 35mm;

Physical and Environmental Characteristics:

Operating temperature: -25℃~70℃

Storage temperature: -40℃~85℃

Humidity: 5%~95%

Non-condensed state weight: 230

ESD performance: air discharge ±15KV, contact discharge ±8KV

Electrical parameter indicators:

Power supply mode: DC 24V|POE power supply

Power consumption: 1W

Circuit protection: with reverse polarity protection

Working frequency: 13.56MHZ

Protocol standard: ISO15693

Support maximum tag capacity: 8K Bytes

Card reading time: Read Time: 30ms each 8Bytes Write Time: 70ms each 8Bytes

Card reading distance: related to the matching read-write head (check the antenna manual of each model)

Communication interface: RJ45

Communication protocol: modbus TCP (Industrial Ethernet)

Description:

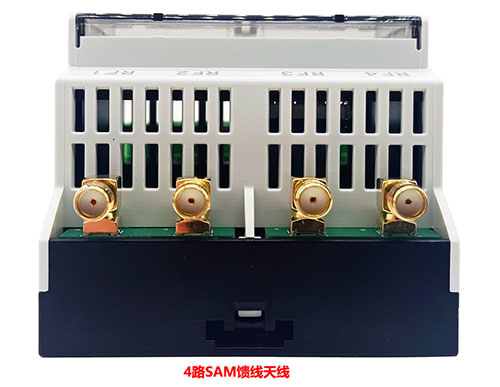

This is a high-frequency four-channel reader based on radio frequency identification technology. The operating frequency of the reader is 13.56MHZ. It supports the reading of I-CODE 2, I-CODE SLI and other labels that conform to the ISO15693 international standard protocol format. The high-frequency four-channel reader supports industrial Ethernet Modbus TCP communication, supports POE power supply, and is convenient for users to integrate into PLC and other control systems. The radio frequency part of the communication protocol is integrated inside the reader, and the user only needs to receive data through the Ethernet interface to complete the reading operation of the tag without understanding the complex radio frequency communication protocol.

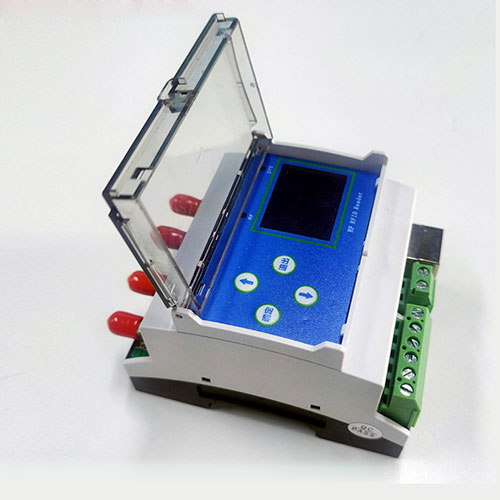

The product is equipped with a liquid crystal display and a working indicator light, which reflects the communication status through the LED of the reader, and can be seen at a glance even in the field. After connecting the signal line and the power line to power on, the yellow light flashes and then stays on, indicating that the initialization is successful. The LCD screen displays as follows, indicating that the device has entered the normal working mode, and the device turns on the RF1 probe by default. Connect the device with the configuration software or serial port assistant on the PC, put a tag in the antenna sensing area, the SYS indicator flashes to indicate the establishment of communication with the host, and the circle next to the antenna logo of the RF indicator indicates that the antenna recognizes the Tag and sends the data to the host.

The reader has been successfully miniaturized, has its own industrial control box to install slide rail clips, easy to install and high reliability, and its own technical advantages have been skillfully integrated into the field of RFID products. It supports four probes at the same time, and the probes stretched by cables can be flexibly installed in processing machinery application scenarios, and support Modbus TCP communication protocol. Widely used in semiconductor automation production lines, PLC control, servo electromechanical systems, power lithium battery production lines, automobile production lines, etc. Automobile strut assembly line, automobile brake pad processing production line, air conditioner assembly line, cooling fan automatic test line, precision Tool management, engine assembly line, component assembly line, compressor production line, intelligent lamp assembly line, intelligent distribution in injection molding workshop, automatic identification of turnover boxes And shunting, refrigerator production line, AGV car and other fields.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China