Power Consumption: 3.5W

Communication ProtocolProfiNet

Communication interface: RS232/Ethernet;

DC power supply: 24V (with reverse polarity and overcurrent protection);

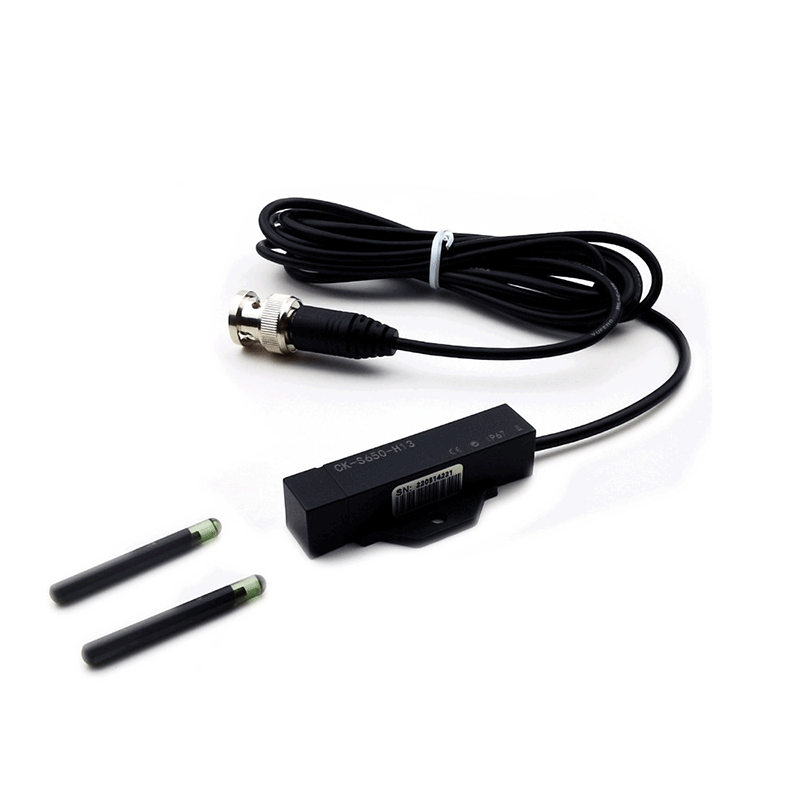

Working frequency: 134.2kHz

Reading and writing card distance: 0~70mm;

Working humidity: 10-90% RH;

Working temperature: -25℃-+70℃;

Working mode: HDX;

RF standard: ISO11784/11785;

Support tags: SIC7999, TI tags (RI-TRP-DR2B-30, RI-TRP-DR2B-40, TRPGP40ATGC, TRPGR30ATGA, TRPGR30ATGB);

Electrical parameters:

◆Working frequency: 134.2KHZ

◆Wireless transmission rate: 2 kbit/s

◆RFID standard: Comply with RFID wireless interface standard (ISO/IEC 18000-2)

◆Semiconductor industry standard: Conforms to SEMI (E4, E5, E99, E15.1, E144-0312)

◆CID carrier type: RI-TRP-DR2B(-30), RI-TRP-WR2B(-30), RI-TRP-IR2B(-30), RI-TRP-RR2B(-30)

◆Sensing range

Reading distance: 0~70mm (related to the performance of the code carrier and the use environment)

Writing distance: 0~60mm (related to the performance of the code carrier and the use environment)

◆Working voltage: DC24V

Work consumption: ≤2.5W

◆Model indication: red LED, green LED

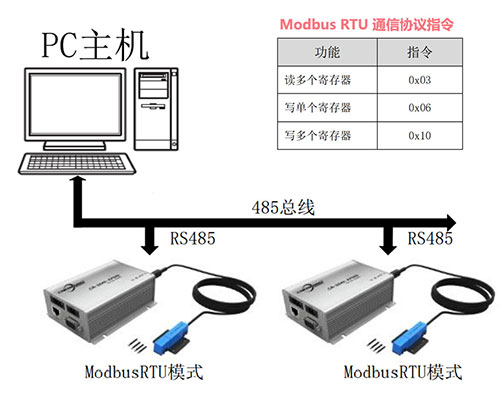

◆Communication interface: RS232 (SECS) - standard configuration

RS485 (modbus RTU) - Optional

Profinet, Modbus TCP-Optional

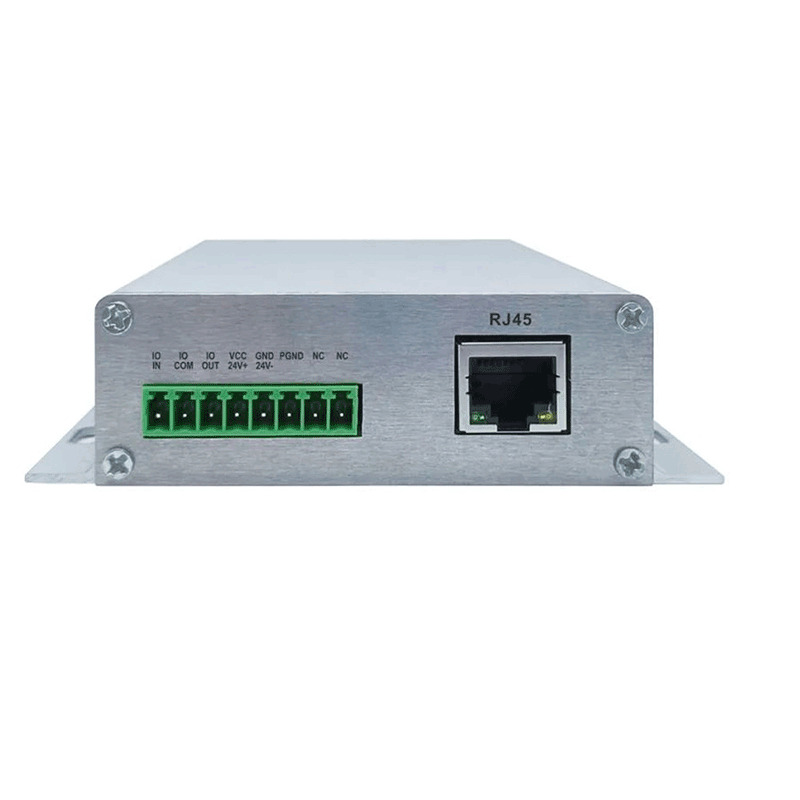

Mechanical properties:

Protection class: IP54

Communication connection: M12×1 connector

Shell material: aluminum alloy

Size: 110mm×70mm×40mm

Weight: about 200g

Descriptions:

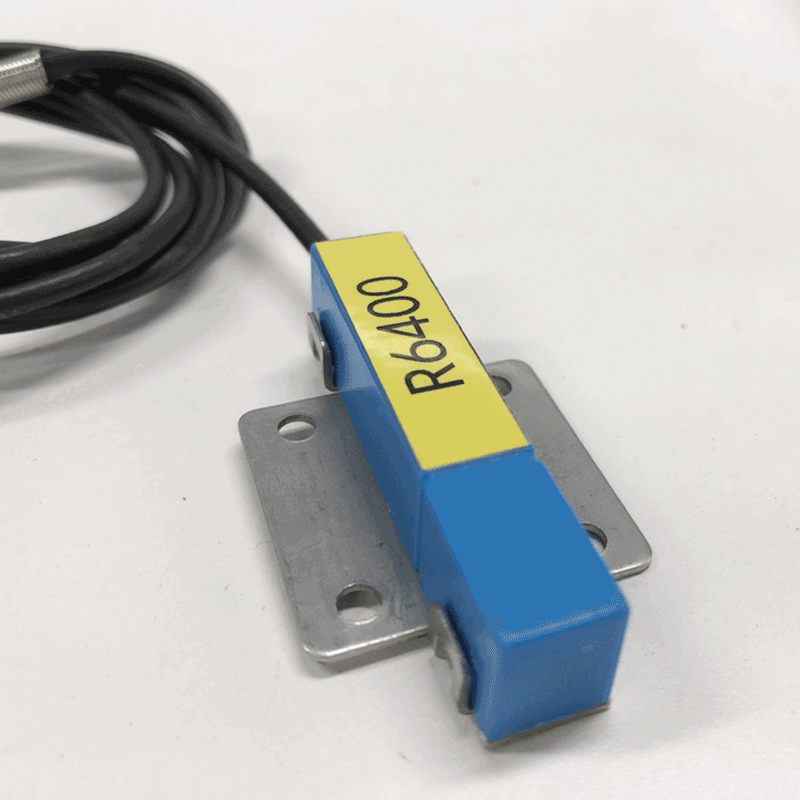

Semiconductor Wafer CAssette RFID Reader and Writer CID Reader/Writer Head SEMI Split Card Reader Amplifier Unit, in line with the world SEMI standard, is an RFID system specially developed for the semiconductor manufacturing industry. CK-S640-AP60E card reader has a working frequency of 134.2KHZ, adopts HDX half-duplex data transmission mode, and is compatible with the CID carrier produced by Texas Instruments. It has excellent read and write reliability and environmental resistance, and maintains production efficiency. It has a wide range of application values in semiconductor manufacturing workshops that require high cleaning resistance.

Semiconductor wafer box RFID reader CID read-write head SEMI split card reader amplifier unit, the communication command follows the SEMI standard, compatible with SECS instructions, and integrates the reader and amplifier functions at the same time, adopts a split layout, and the read head is small in size (Customizable), high integration, etc., can be seamlessly connected to existing semiconductor production equipment. It is suitable for wafer handling AGV vehicles with limited installation space, wafer turntables, logistics, warehouse management, process control, robotic arm site control and other fields.

Semiconductor automation production line, power lithium battery production line, automobile production line, etc. can be widely used to identify RFID Insert (plug-in), RFID Wafer Cassette (wafer box), radio frequency identification wafer box in the field of semiconductor automation production. Tag identification, reading, writing. RFID wafer box information can be quickly identified through radio frequency signals, providing data basis for automated semiconductor production, facilitating production management and wafer tracking and identification, and greatly improving the efficiency of automated semiconductor production. Semiconductor RFID Card readers, readers, and readers can support RFID silicon wafer boxes, wafer boxes, flower baskets, semiconductor IC special boxes, packaging boxes, carriers, PFA flower baskets, and Teflon in different formats, shapes, materials, and applications. Dragon cassette, Teflon crystal boat box, wafer carrier, crystal boat box, Glass PEEK Cassette, square glass temperature-resistant crystal boat, anti-static flower basket, semiconductor flower basket, etc.

Such as: Frame Box installs RFID wafer box, FOUP installs RFID wafer box, photomask box installs RFID Holder, PFA CST installs RFID Holder, PEEK CST installs RFID Holder, chemical process card hook-in type PFA material RFID wafer box, General process card hook-in PC material RFID wafer cassette, general process ultrasonic welding PC material RFID wafer cassette, slotted external high temperature resistant PEI+CF RFID wafer cassette, acid and alkali scratchable external PTFE Material RFID wafer box, general process sticky PC+3M glue material RFID wafer box, general process card hook-in type PEEK+CNT material RFID wafer box, general process card PEEK+CNT material RFID wafer box, general Process embedded PP material RFID wafer box, acid-base process embedded PVDF material RFID wafer box, general process lock type PP material RFID wafer box, general process button type thermosetting plastic material RFID wafer box, General process adhesive type white dragon sticker material RFID wafer box.

Contact: Adam

Phone: +86 18205991243

E-mail: sale1@rfid-life.com

Add: No.987,Innovation Park,Huli District,Xiamen,China